Polycore™

The most versatile lightweight building panel in the world!

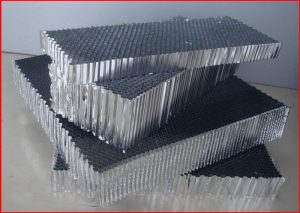

Suppliers of advanced structural honeycomb cored panels.

We supply to:

We supply to:

- Transport,

- Aeronautics,

- Marine,

- Building,

- Caravan,

- Leisure industries.

It’s Economical, Ultra Light! and Ultra Strong!!

It is also Enviromentally Friendly!!

This product is recyclable!!!

The following refers to the core material only not large composite panels.

Polycore honeycomb Core products can be processed into various sandwich panels using Polycore Polypropylene Honeycomb as the core. Different surface materials are available, such as steel, aluminium, wood, reinforced fiber glass, etc.

Honeycombs are widely used when it comes to sound reduction.

Features like corrosion resistance, fungi resistance, small pressure losses give these products their unique position in the market place.

The uniform collapsing of the tubes in the honeycomb system leads to an outstanding energy absorption behavior.

Polycore Honeycomb core panels manufactured in an ISO 9001/2000 certified factory.

Polycore is the only thermoplastic honeycomb core material to be approved for use by the National Space Administration in China.

Other features of Polycore include:

- Polycore Polypropylene FR panels pr

oduce zero ignition and zero spread of flames.

oduce zero ignition and zero spread of flames. - the strongest in the market.

- produces the thinnest core in the market.

- the most technologically advanced.

- Polycore honeycomb panels are manufactured as a single sheet, not by joining small sheets together.

- Polycore honeycomb panel surfaces are completely flat and without trapped air, which facilitates lay-up.

- extremely low resin wastage.

- skin facings are thermally welded to our advanced structural honeycomb core, hence no known delamination issues.

- available in different grades of strength.

If you want quality then you want Polycore!

Polycore™ and Polycore Honeycomb™ are trademarks of Polycore

Personal Transporter Built By Peter Wing From Canberra.

.

Polycore Polypropylene Honeycombs are widely used in the following industries.

Marine Industry:

Hulls, bulkheads, decks, soles, furniture, lockers, engine room sound insulation, dingy’s.

Hulls, bulkheads, decks, soles, furniture, lockers, engine room sound insulation, dingy’s.

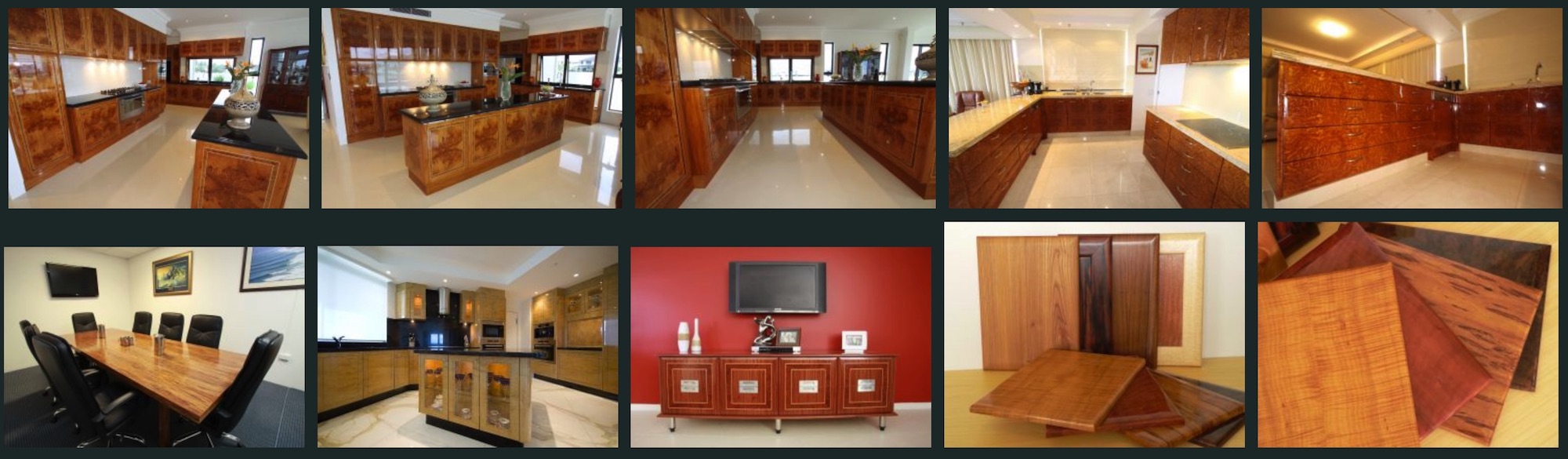

Building Industry:

Walls, suspended ceilings, floors, doors, decks, showers, kitchens, furniture, outdoor furniture, patio’s, gazebo’s, office dividers.

Transport Industry:

Truck and trailer floors, pantech bodies, horse floats, race car transporters, dividers, partitions etc.

Aviation Industry:

Bulkheads, floors, lockers, luggage compartments, ultra light ultra strong freight containers, ultra light aircraft.

Theatrical Industry:

Props, scenery, noise reduction barriers, lightweight stage construction.

Caravan and Trailer Industry:

Caravan construction, including floors, roofs, walls, cupboards, furniture.

Lightweight trailers, site offices, transportable homes, dongas.

Filter systems:

Filter systems either air or fluid, in air as end plates with activated carbon in between, or stacked as fluid filter plates.

These are but a few of the uses Polycore Polypropylene Honeycomb Core Panels can be put to.

I am sure you can think of a lot more!